Components of automatic winding machine and application of numerical control technology

- 来源:广东君益智能科技有限公司

- 发布日期:2024-03-25

- 访问量:1022 次

- 所属栏目:Company

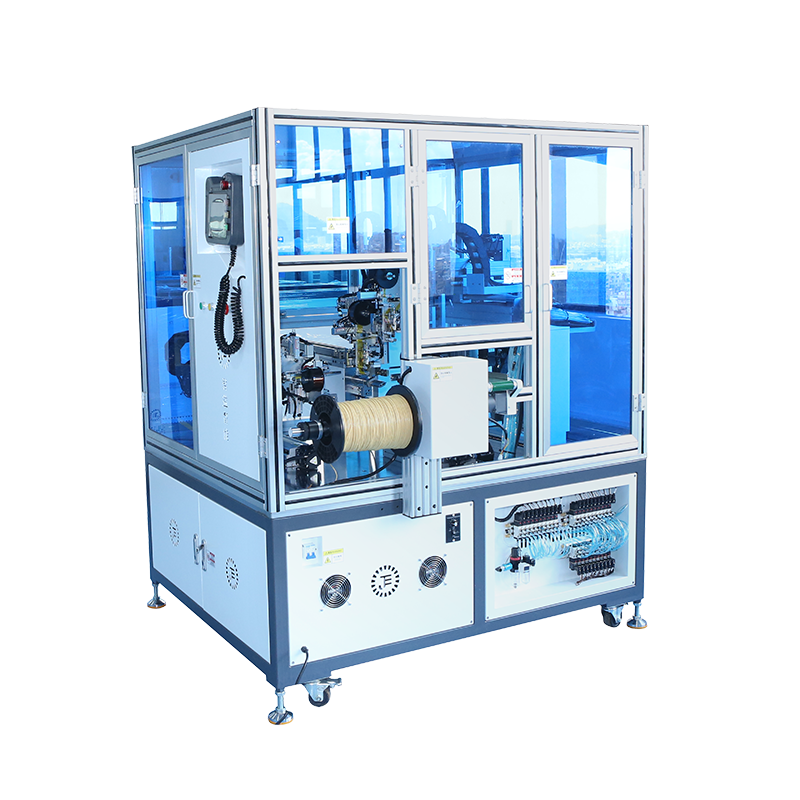

A winding machine usually consists of the following components: 1. Equipment body 2, electrical control system 3, driving device 4 and functional accessories.

First, the equipment fuselage This is the main body of the winding machine, which mainly refers to the frame, object, spindle and other major mechanical parts.

According to the different requirements of winding processing, it can be divided into various winding machines, such as vertical, horizontal, desktop,

Automatic winding machine

Wait a minute. Automatic winding machine Because the numerical control system is a highly automated equipment, its structure must meet the requirements of automatic production, so the body structure of automatic winding machine is to a large extent specially designed.

Second, the electrical control system This is the core of the automatic winding machine, including the display interface, operation interface, computing components and storage functional components.

The numerical control system of modern automatic winding machine is mostly controlled by computer. The numerical control system has the following main functions: linkage control (multi-axis linkage); Interpolation of various functions; Transformation of various programming codes; Various forms of data input; Selection of various winding modes; Fault self-diagnosis and so on. So we call CNC system CNC system.

Because CNC system is the core of winding machine, the technical level of automatic winding machine depends on the technical level of CNC system to a great extent. And the control software is the key to this core. At present, many winding machine manufacturers in China have developed high-level control software by themselves.

Third, the driving device This is the driving part of the winding machine actuator. Mainly includes the spindle drive unit, the drive unit of the wire arranging shaft, the spindle motor and other drive motors.

The spindle system of common winding machine is driven by motor to realize transmission and speed change. The motion of the spindle and wire arrangement of the automatic winding machine is instructed by the numerical control system and realized by the action of the controller and the stepping system. In this way, there are some special requirements for the driving device of automatic winding machine. For example, the servo drive of automatic winding machine should have good quick response ability, and can accurately and sensitively track the instructions issued by the numerical control system to realize quick start, speed change and stop.

Four, auxiliary device refers to some necessary supporting parts of automatic winding machine.

Auxiliary devices cover a wide range, including almost a series of electrical and pneumatic equipment on the winding machine. Because the auxiliary devices have a great influence on the realization of the function of automatic winding machine, great progress has been made in the matching and development of these auxiliary devices in China, and the localization rate has been very high.

Compared with traditional winding machines, automatic winding machines have many outstanding advantages.

Automatic winding machine

It can complete the processing of many complex coils that are difficult or impossible for traditional winding machines to complete; Can greatly improve the precision of wire arrangement and stabilize the quality of products; Can greatly improve productivity, but also the inevitable trend of industry development.