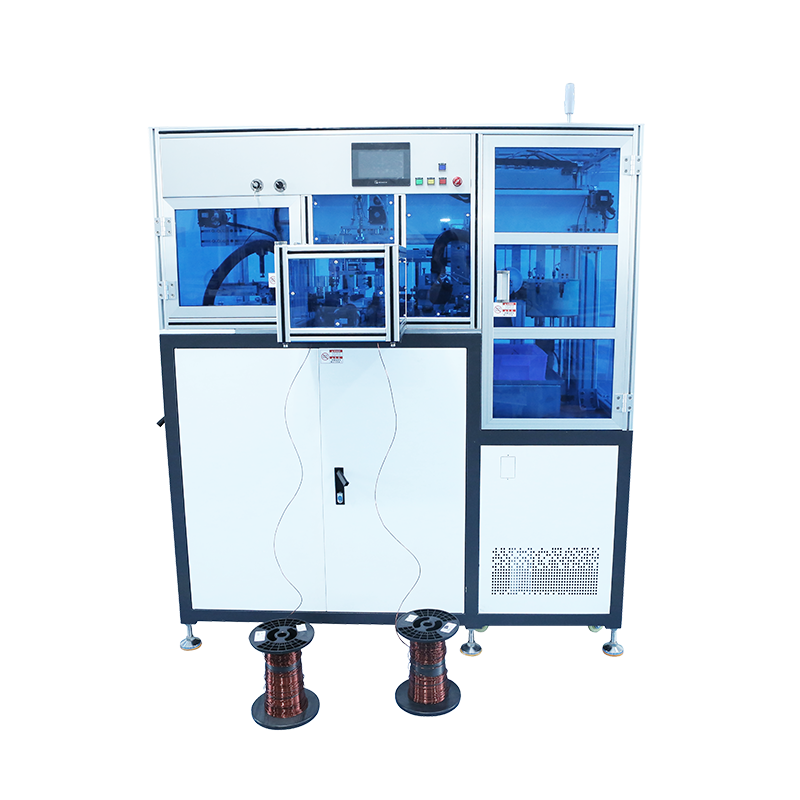

How does the automatic magnetic ring winding machine work?

- 来源:广东君益智能科技有限公司

- 发布日期:2024-03-25

- 访问量:1030 次

- 所属栏目:FAQs

一. How is the automatic magnetic ring winding machine wound?

1. Take the magnetic ring that has not yet been wound with copper wire.The magnetic ring with winding copper wire needs to stop at a specific position through the conveyor belt, and the sensor detects

whether it stops at the specified position. At this time, the manipulator picks up the magnetic ring and puts it on the fixture at the winding position to prepare for winding;

2.copper wire feeding, copper wire through the pulley and other components, through the nozzle, clamped by a clamp, at this time, use pneumatic scissors to cut the wire at a fixed position near one end spool. Make the length of the wire

at a fixed value, which is convenient for winding and saves wires. The length of the wire can be set in advance. By calculating the size of the magnetic ring, the diameter of the wire and the number of turns, the required length

of the wire can be calculated. After these materials are aligned, you can start winding.

3. The section between the cut thread connecting clip and the wire nozzle is just above the magnetic ring. The crochet needle passes through the magnetic ring from the lower part of the magnetic ring upwards,

forming a cross state with the thread. When the crochet needle is recycled, it just hooks the thread. Because one end is fixed, the other end of the thread passes through the magnetic ring from the center of the magnetic ring, and then is

clamped by anotheclip, and then winds back to the upper part of the magnetic ring from the outside of the magnetic ring, thus completing the winding of a circle.

4. The fixture for clamping the magnetic ring can rotate clockwise and counterclockwise around the center of the magnetic ring, and the rotation distance and time can be set, so that the position and interval

distance of each circle in the winding process can be adjusted.Meet the requirements of magnetic ring production.

When the magnetic ring clamp clamps the magnetic ring, it occupies a part of the magnetic ring, it can't be wound around this part when winding,so the automatic magnetic ring winding

machine is oftensuitable for common mode winding and 340 winding.

In addition, the crochet needle realizes reciprocating motion, and there is a problem of maximum stroke, which is to hook the thread once. It's about threading all the wires through the magnetic ring, so that the next loop can be wound. If

the thread does not completely pass through the magnetic ring, the next loop cannot be wound. The crochet reciprocates up and down, and the machine is not infinitely high, nor can it be made too high, so the

movement stroke of crochet is limited. Therefore, the length of the wire we wound is also limited. Generally, 1-1.6m is more suitable.